Top Reasons for Using Plants to Make Biologics

In this blog we’ll look at the top reasons for using plants to make biologics, and explain the many benefits a plant-based system can offer.

Plant-based technologies have existed for the past 30 years, however it is not until recently that their potential for rapidly being able to produce therapeutics, such as vaccines have been widely recognised. The COVID-19 pandemic has shone a light on plant-based biologics (GSK and Medicago collaboration and Kentucky Biopharma) with the world looking for fast, inexpensive, and efficient production platforms to build up treatments in the event of future epidemics and pandemics.

Top Benefits

There are many advantages to using a plant-based system over more commercially well-known alternatives such as mammalian, E.coli, and yeast cell-based productions. Below we’ll highlight some of those benefits and importantly explain why a plant-based system is a worthwhile investment on many different levels.

1. Reduced contamination risk

There is a reduced risk of human-threat contaminations when producing biologics in a plant-based system, this is because there are no animal-derived products used within the process. Potentially dangerous contaminants, such as viruses that are required to be controlled stringently in mammalian cell cultures, do not occur in plants.

2. Low maintenance

The infrastructure requirements for growing plants are significantly lower than for bioreactor-based facilities and processes. While plant-based facilities need to be controlled environments (simple chemically defined media, light, humidity, temperature, O2, and CO2 levels), the plants themselves do not need to be grown in GMP classified spaces.

3. Readily scaled-up

The simplicity of plants enhances their scalability, if you want more recombinant material, it’s easy, you just need to grow more plants.

4. Projected lower capital costs

The more established production processes typically use genetically engineered cells to make the drugs in expensive stainless steel, or single-use plastic bioreactors. The expected running costs of a facility such as this would be around 25% more expensive than that of a GMP plant-based facility because growing and nurturing plants is less labour and consumable intensive.

5. Simple generation of high biomass

Plant-based expression systems do not require scaling of complex media, unlike a traditional cell-based bioreactor system. You just grow more plants to generate a large amount of biomass to produce biologics.

6. Expression of ‘toxic proteins’

Utilising plant-based expression systems that are transient, expression and accumulation of the protein of interest occurs within a few days and because it happens so quickly the plant often does not have the time to recognise the toxicity of the protein. In addition, a protein from another organism, for example human, may not be recognised within the plant as toxic.

7. Eukaryotic system produces a wide range of posttranslational modifications

Plants are eukaryotic organisms and therefore perform a vast array of post-translational modifications including phosphorylation, glycosylation, ubiquitination, methylation to name a few. Proteins formed with their correct posttranslational modifications have a better chance of producing a correctly formed molecule resulting in a functionally active protein.

8. Bench to bedside savings

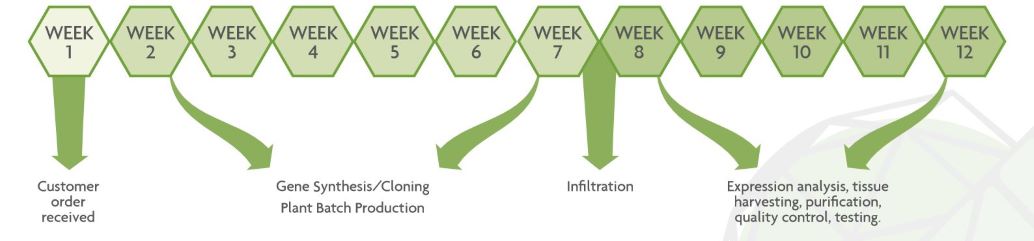

Downstream processes remain much the same in terms of timeline, upstream processes however are far simpler and quicker, as a result quicker with earlier stop/start decisions being made possible due to rapid identification of success or failure of a product. The speed of the production enables R&D programmes to be accelerated, resulting in developing products more quickly, and ultimately extending patent lives by seven months or more.

Find out what a plant-based expression system could do to help accelerate your products’ route to market by speaking to one of our experts at Leaf Expression Systems.

Contact us here or speak directly to our Business Development: williamsl@leafexpressionsystems.com